Fiber wood FiberTherm Base density 250kg/m³

Fiber wood panels with density 250 Kg/m³.

Fiber wood Fibertherm Base is a panel for thermal and acoustic insulation with high compressive strength, ideal for flat roofs and flooring system that can be walked on.

The FiberTherm Base 250 fiber wood panel is a rigid and completely ecological thermal insulation ideal for the construction of dry and wet screeds, and floors that can be walked on thanks to its high compressive strength (150 kPa), with a density of 250 kg/m³, and its properties of impact sound insulation.

The material is also recyclable, it is certified and made exclusively with wood from controlled forests in compliance with the FSC guidelines (Forest Stewardship Declaration).

The insulating fiber wood panel Base 250 is an excellent material to realize dry and wet screeds, flooring systems and walkable floors:

• optimal combination for dry and wet screed construction, highly resistant to compression;

• ecologic insulation of roofs, floors and attics;

• suitable for insulating and bituminous panels;

• excellent insulating properties, both in summer and in winter;

• breathable, favors a comfortable and healthy environment;

• recyclable, ecologic, environment-friendly;

• building material tested and authorized according to current European standards.

Available sizes

fiber wood panels with sharp edges

| Thickness | Size mm | kg/m² | Pan./pallet | m²/pallet | kg/pallet |

|---|---|---|---|---|---|

| 20 mm | 1350 x 600 | 5,00 | 112 | 90,7 | approx.460 |

| 40 mm | 1350 x 600 | 10,00 | 56 | 45,4 | approx.460 |

| 60 mm | 1350 x 600 | 15,00 | 38 | 30,8 | approx.470 |

| 80 mm | 1350 x 600 | 20,00 | 28 | 22,7 | approx.460 |

| 100 mm | 1350 x 600 | 25,00 | 22 | 17,8 | approx.460 |

Technical characteristics

| Characteristics | Values |

|---|---|

| Density kg/m³ | 250 |

| Fire reaction according to EN 13501-1 | E |

| Coefficient of thermal conductivity λD W/(m∗K) | 0,048 |

| Specific heat J/(kg∗K) | 2.100 |

| Resistance to vapor diffusion μ | 5 |

| sd value (m) | 0,1 (20)/ 0,2(40) /0,3(60) 0,4(80)/ 0,5(100) |

| Thermal resistance RD (m²·K)/W | 0,40(20)/ 0,80(40) /1,25(60) 1,65(80)/ 2,05(100) |

| Bending resistance 10% of compression (N/mm²) |

≥0,15 |

| Compressive strenght (kPa) | ≥150 |

| Resistance to tearing (kPa) | ≥10 |

| Compressive strength relative to lenght [(kPa·s)/m²] |

≥100 |

| Panels identification | WF-EN13171-T5-DS(70,-)2 -(10/Y)150-TR20-MU5 |

| Waste code (EAK) | 030105/170201 |

Solutions with fiber wood Fibertherm Base

Dry screed with fiber wood Base

Flooring system using fiber wood panels with high density and excellent compression resistance Fibertherm Base and cement bonded particle boards BetonWood.

Fiber wood shop Base and concrete screed

Flooring system using fiber wood panels Fibertherm Base with high density and high thermal insulation, concrete constructional work and cement bonded particle boards BetonWood.

Screed with fiber wood on corrugated sheet

Screed system on corrugated metal sheet with high density and high compression resistance fiber wood Fibertherm Base and a double layer of cement bonded particle boards BetonWood.

Radiant screed with fiber wood Base

Radiant natural screed BetonRadiant with thermal and acoustic insulation in high compression resistance fiber wood panels Fibertherm Base.

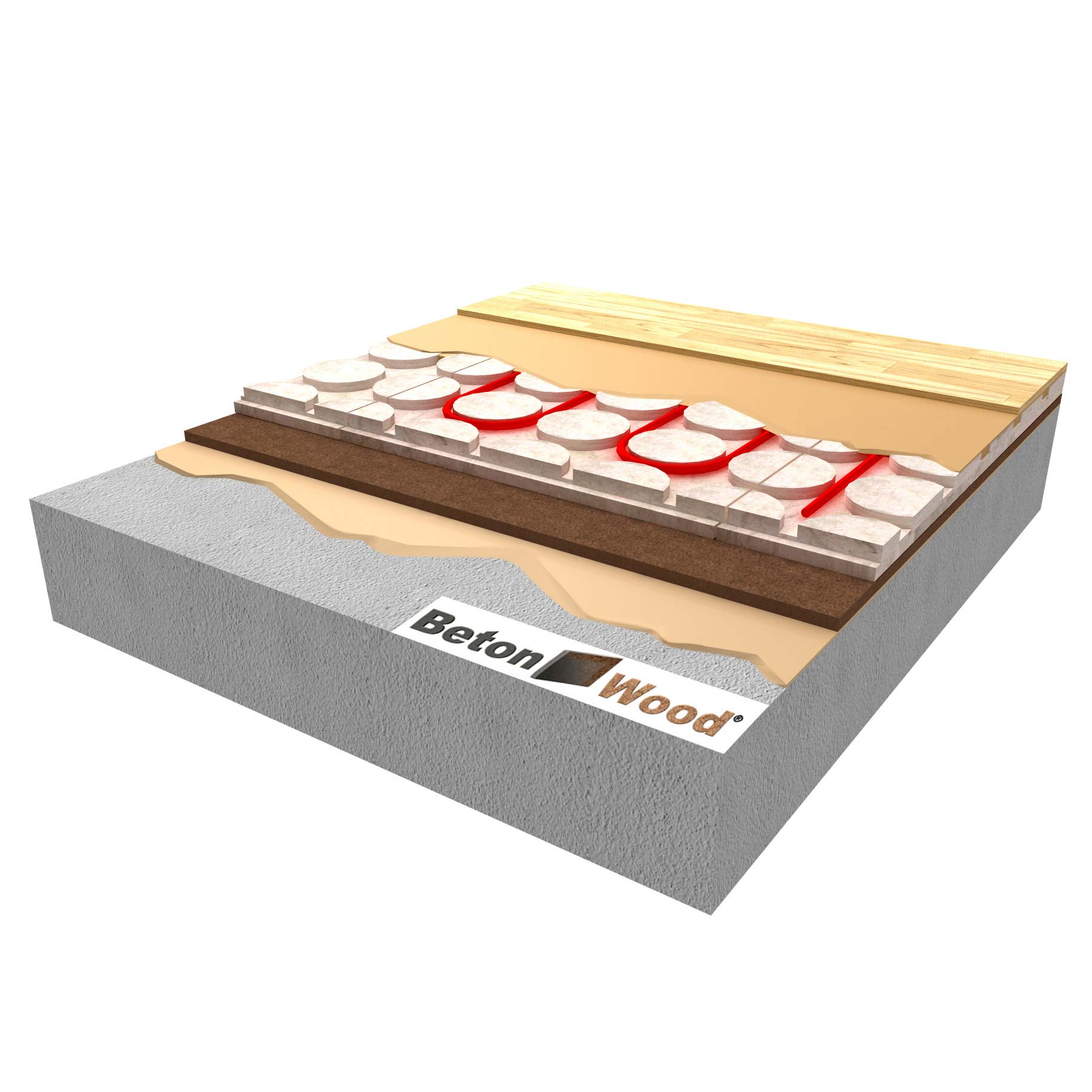

Radiant screed with fiber wood Base on wooden floors

Radiant natural screed BetonRadiant with thermal and acoustic insulation in high compression resistance fiber wood panels Fibertherm Base on wooden floors.